CALCIUM CARBONATE

MANUFACTURED PRODUCTS AND APPLICATIONS

Souter’s high calcium limestone can be used in a wide range of manufactured products. The applications include fillers bound in various cementitious, liquid asphalt or polymeric matrices. These include packaged lime or Portland Cement based products, asphalt roofing products, as well as fiberglass, container and float glass.

AGRICULTURAL PRODUCTS AND APPLICATIONS

High calcium micritic limestone products available from Souter are an excellent choice for poultry (breeders, broilers, layers), ruminants, swine and equine feed. Souter has products available in three sizes which can be used in meal, pellets, liquid or various extruded feed product and nutrient applications. In addition, Souter provides a high calcium limestone fertilizer filler suitable for field bulk or packaged products. Calcium carbonate products of various sizes are also commonly used in rice polishing or as flow aids in grain milling operations. Finally, our fine products can be used for soil amendments for horticulture including mushroom farming and manufactured soils

CHEMICAL APPLICATIONS

About the Material

Mineralogic calcium carbonate (high calcium limestone) generally comes in three forms or origins: micritic, oolitic and crystalline. Although origin and structure are generally specific to the material by source, there can be combinations of origins present. Souter’s limestone in Gore, OK is mined from the St. Clair formation and is: micritic in origin, very fine grained and generally light buff to light grey in color.

Souter’s new high calcium limestone plant.

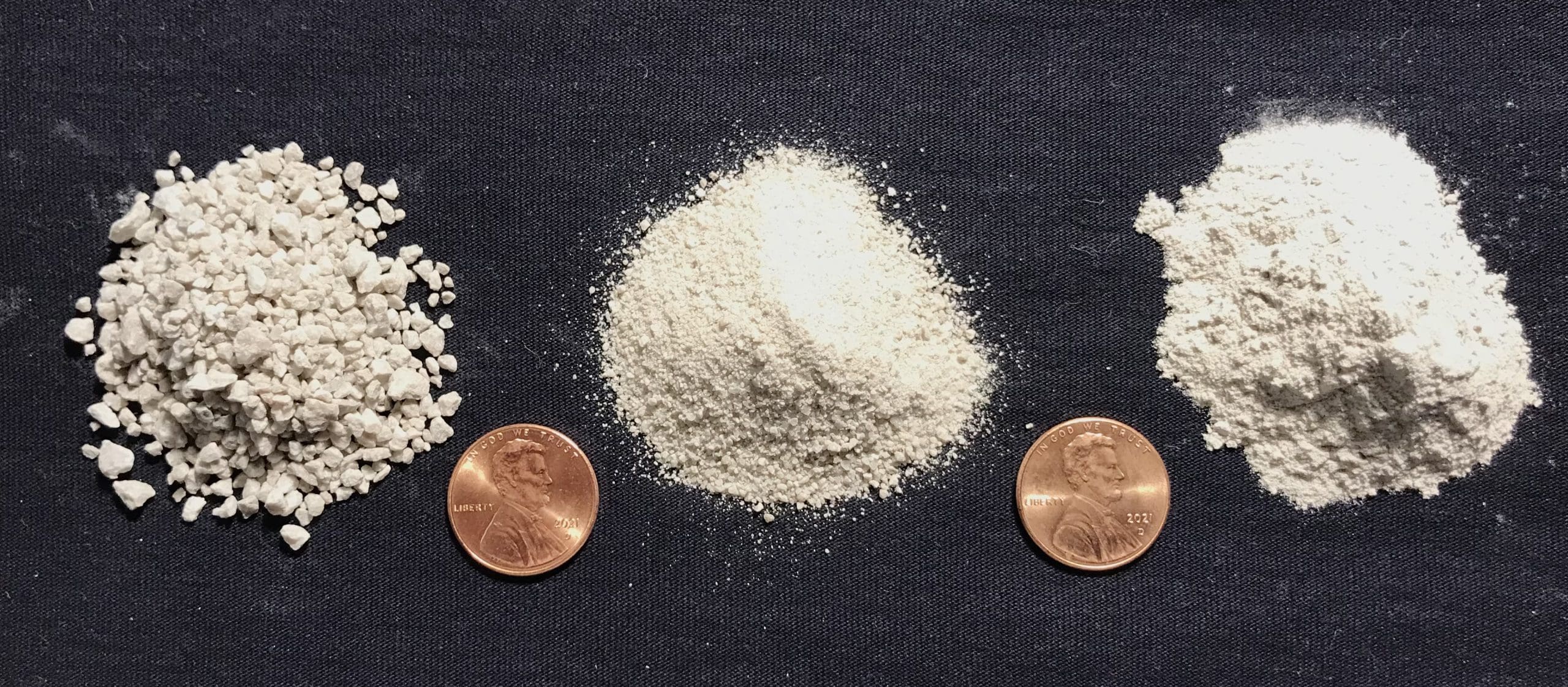

Surface porosity of micritic calcium carbonate is generally higher than that which is either oolitic or crystalline in origin, making it a sound choice where bond strength is important (i.e. cement or polymer matrix) or when reagent properties are important in chemical applications such as: flue gas desulfurization, oil and gas field applications, soil amendments, animal feed or glass manufacturing. Souter Limestone products are milled in our newly commissioned, state of the art processing plant designed to produce three grades of dry products:

- #6 x #16 mesh (HC 102) – for poultry breeder and layer feed and fertilizer filler applications;

- #16 x #100 mesh (HC 101) – for container and float glass as well as for poultry and animal feed;

- Minus #100 mesh or less (HC 103) – for feed, asphalt roofing products, oil and gas, matrix filler and chemical applications.

Souter has the ability to load pneumatic, hopper bottom and dump trailers and has access to transload facilities for rail and barge.